Commercial building owners face a significant decision between EPDM and TPO roofing systems. EPDM’s proven track record spans 40 years, while TPO remains a relatively newer market option. The durability difference stands out clearly – EPDM roofing systems can last 20-30 years, but TPO systems typically reach 15-20 years.

The cost comparison reveals EPDM’s price range of $4 to $10 per square foot, while TPO costs between $5 and $12. TPO demonstrates superior strength with triple the puncture resistance of EPDM. The environmental edge goes to EPDM because it’s 100% recyclable.

This piece breaks down these roofing materials to help you pick the right option for your commercial building. You’ll learn everything about their material composition and maintenance needs that will impact your long-term investment.

Understanding EPDM and TPO Roofing Materials

The way roofing materials are built and structured plays a big role in how well they work on commercial buildings. EPDM and TPO each have unique compositions that shape their durability, installation needs, and how well they perform.

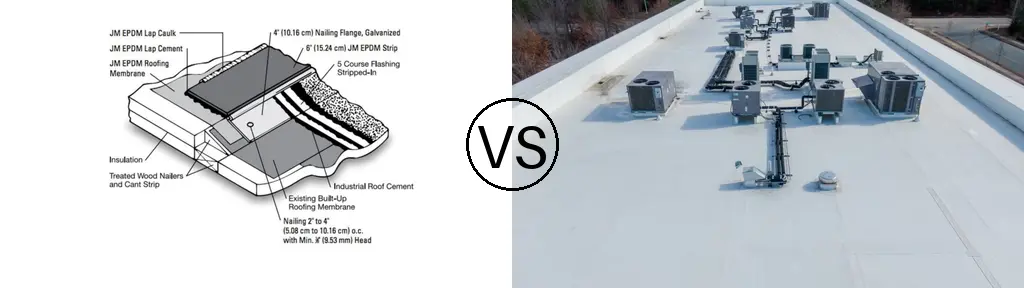

Composition and Structure of EPDM Roofing

EPDM (Ethylene Propylene Diene Monomer) is a synthetic rubber membrane made from ethylene and propylene. This single-ply roofing material comes in thicknesses from 45 to 60 mils (0.045 to 0.060 inches). The carbon black in EPDM gives it a dark color that absorbs heat instead of reflecting it. The material stays flexible even in extreme weather and resists cracking and tearing. The sheets come in wide rolls—up to 50 feet across—which means fewer seams during installation. These seams are sealed with liquid adhesives or special tape, and they can become weak points in the system as time passes.

Key Properties of TPO Roofing Systems

TPO (Thermoplastic Polyolefin) blends polypropylene and ethylene-propylene rubber into one membrane, with polyester reinforcement for extra strength. TPO has a white surface that reflects UV rays, which can lower cooling costs in warm climates. You can get TPO in thicknesses from 45 to 80 mils to match different building needs. One of TPO’s best features is its hot-air welded seams that create bonds stronger than the membrane itself. The material remains flexible yet tough against punctures and tears throughout its life.

The Difference Between EPDM and TPO Roofing

EPDM and TPO differ mainly in their chemical makeup—EPDM is a thermoset material that won’t remelt after curing, while TPO is thermoplastic and can be heat-welded. EPDM needs adhesives for seams, which takes more labor but is technically simpler to install. TPO requires special heat-welding equipment that creates stronger seams but needs more technical skill. EPDM’s dark surface soaks up heat, but TPO’s white surface meets cool roofing standards. Both materials keep water out well but handle stress differently—EPDM handles UV and ozone exposure better, while TPO stands up better to punctures and oil.

Free Roof Inspections. Fast. Reliable.

Is your roof ready to weather the storm? Dont risk property damage. Our free roof inspections provide expert analysis to identify potential issues before they become costly problems.

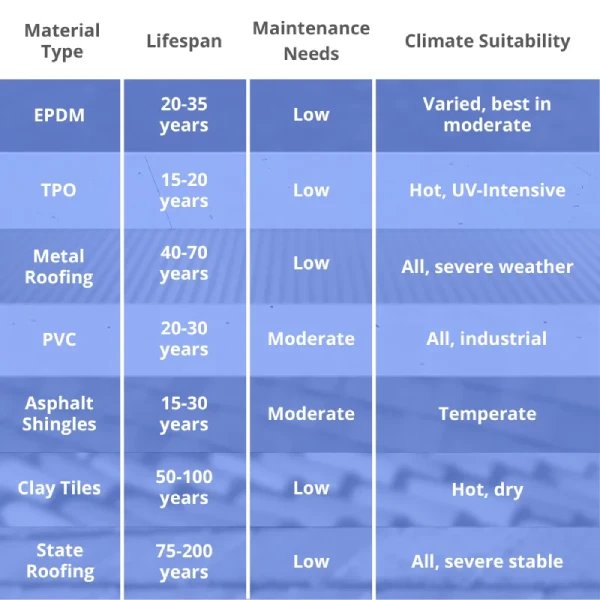

Lifespan Comparison: EPDM vs TPO Roofing Material

The lifespan of materials plays a crucial role in commercial roofing investment decisions. Different materials can substantially affect your building’s economics and performance over time.

Average Lifespan of EPDM Roofs (25-40 Years)

EPDM roofing systems have built a solid reputation for exceptional durability in commercial buildings. These rubber membrane roofs last 25-40 years with proper installation and maintenance. EPDM’s simple molecular structure gives it excellent resistance to ultraviolet radiation, ozone, and weathering. The material stays flexible throughout its lifecycle and expands and contracts with building movements without cracking or splitting. Many EPDM roofs from the 1980s still function well today, showing their remarkable durability even under harsh conditions.

Expected Longevity of TPO Roofing (15-25 Years)

TPO roofing systems offer a shorter service life of 15-25 years. TPO’s performance continues to evolve as manufacturers update their formulations. The material’s shorter lifespan compared to EPDM comes in part from its greater sensitivity to heat aging and weathering over time. The material’s reflective properties help save energy throughout its service life, which can balance out some longevity drawbacks when choosing between EPDM and TPO roofing.

Factors That Affect Durability of Both Materials

Several key factors determine the lifespan of both roofing systems:

- Installation quality: Skilled installers and careful application directly affect how long the roof lasts

- Roof slope and drainage: Pooled water speeds up deterioration in both materials

- Maintenance frequency: Regular checks and quick repairs help extend the roof’s life

- Local climate conditions: Temperature changes, UV exposure, and rainfall patterns affect each material differently

- Membrane thickness: Thicker membranes (60-90 mil) last longer than thinner options

Environmental Factors Affecting Roof Longevity

Environmental conditions around commercial buildings determine which roofing material will work best over time. Property owners can make better decisions by learning about how external factors interact with EPDM vs TPO roofing materials in their location.

How UV Exposure Impacts Each Material

UV radiation affects these roofing systems in different ways. EPDM’s carbon black content acts as a natural UV absorber that provides exceptional protection against solar degradation. This built-in sunscreen helps EPDM maintain its structural integrity even after decades in the sun. TPO uses chemically engineered UV inhibitors and reflective properties to curb degradation. These protective additives work well at first, but they can break down over time. This makes older TPO installations more vulnerable to UV damage. The difference between EPDM and TPO roofing becomes clear especially when you have high-altitude or southern locations with intense UV exposure.

Temperature Fluctuations and Material Performance

Both materials face tough tests from extreme temperature changes. EPDM stays flexible and pliable even at -40°F, which stops it from cracking during freeze-thaw cycles. On top of that, its heat absorption properties work well in colder climates. TPO shines in high-temperature environments because its reflective surface minimizes heat absorption. Some TPO formulations might struggle with repeated expansion and contraction, especially at the seams. Your choice between TPO vs EPDM roofing should factor in how often and severe the temperature changes are in your area.

Regional Climate Considerations for Material Selection

Your region’s climate patterns should guide your material choice. EPDM works great in northern regions with heavy snowfall because it stays flexible and resists impact damage from hail or fallen branches. Southern states with intense sunshine and high cooling costs benefit from TPO’s reflective properties that lead to energy savings. Coastal areas create unique challenges since salt spray affects EPDM vs TPO roofing differently. Buildings in hurricane-prone zones might do better with EPDM because it resists wind uplift better and has fewer seams.

Maintenance Requirements and Long-Term Costs

The value you get from commercial roofing depends on more than just proper installation. Your roof needs regular upkeep. EPDM and TPO roofing systems have different maintenance needs that affect both immediate work and long-term costs.

EPDM Maintenance Schedule and Common Issues

EPDM roofs need a simple maintenance approach. You should get professional inspections twice a year – best done in spring and fall. The basic upkeep includes keeping the surface clean, clearing debris, and checking seams where adhesive might wear down. EPDM roofs often develop seam problems after 10-15 years. These weak points show up throughout the roof’s life. The good news is that you can usually fix specific spots instead of replacing the whole roof.

Water pooling is another issue that needs attention. Even the toughest EPDM membrane can break down if water sits too long. Repairs usually need special liquid adhesives or seam tape. Experienced Roofing contractors find these fixes straightforward.

TPO Upkeep Needs and Repair Frequency

TPO systems also need checks twice a year but come with their own challenges. The heat-welded seams work better than EPDM’s glued connections for the first ten years. You’ll see fewer early seam failures. All the same, TPO membranes can crack on the surface as they age, especially where sun exposure is intense.

Fixing TPO takes special heat-welding equipment. Building managers can’t handle these repairs themselves. You’ll need professionals even for small fixes, which can make maintenance costs add up.

Comparing Lifetime Maintenance Costs

Looking at the total cost of TPO versus EPDM roofing brings up several key points. EPDM needs more seam repairs over its life, but these fixes are affordable. TPO might need fewer repairs at first, but each fix costs more because it needs special tools and expertise.

The biggest difference between these materials shows up near the end of their life. You can add a coating to EPDM that gives you 10-15 more years of use. This saves money by pushing back full replacement. TPO doesn’t work well with these life-extending treatments. You might end up replacing a TPO roof sooner, even though it costs about the same to install.

Comparison Table

| Characteristic | EPDM | TPO |

|---|---|---|

| Material Composition | Synthetic rubber (ethylene and propylene) | Thermoplastic polyolefin with polyester reinforcement |

| Average Lifespan | 25-40 years | 15-25 years |

| Cost per Square Foot | $4-$10 | $5-$12 |

| Thickness Range | 45-60 mils | 45-80 mils |

| Color/Surface | Dark, heat-absorbing | White, reflective |

| Seam Type | Adhesive or tape-secured | Hot-air welded |

| UV Resistance | Excellent (natural carbon black protection) | Chemical UV inhibitors that degrade over time |

| Temperature Performance | Flexible down to -40°F | Better performance in high temperatures |

| Puncture Resistance | Lower | Three times more resistant than EPDM |

| Maintenance Requirements | Bi-annual inspections, frequent seam repairs | Bi-annual inspections, fewer early seam issues |

| Repair Complexity | Simple repairs, uses adhesives | Complex repairs, requires specialized heat-welding |

| End-of-Life Options | Can be coated to extend life 10-15 years | Limited rejuvenation options |

| Recyclability | 100% recyclable | Not mentioned |

| Maximum Roll Width | Up to 50 feet | Not mentioned |

Conclusion

Commercial building owners can pick between EPDM and TPO roofing systems. Each system brings its own benefits to the table. EPDM shines with a remarkable 25-40 year lifespan, solid performance history, and easy upkeep. TPO might be better at handling punctures and reflecting heat, but its 15-25 year lifespan needs a second look.

Weather conditions make a big difference in picking the right material. EPDM works great where temperatures swing wildly, and TPO shows its strength in warmer areas where heat reflection is vital. Money matters too. EPDM’s cost runs $4-$10 per square foot, which gives you better value than TPO’s $5-$12 range.

These systems need different kinds of care. EPDM’s seams need regular checks but fixes are straightforward. TPO doesn’t need attention as often, but when it does, the work gets complicated. Looking at long-term value, EPDM can last even longer with coating applications – something you can’t do with TPO.

Expert advice is a great way to get help with this vital choice. Skilled roofing contractors can give you the full picture of your building’s needs and local weather patterns to suggest the best fit. Building owners who want expert input on their roofing projects can connect with roofing specialists at +1 (503) 430-7178 or email [email protected] for tailored suggestions.

![EPDM vs TPO Roofing: Which Lasts Longer on Commercial Buildings? [2025]](https://roofrivercity.com/wp-content/uploads/2025/03/epdm-vs-tpo-roofing.webp)